PC USB CONTROL OF THE LHIRES III NEON

CALIBRATION LAMP

(Updated 19 Aug 2008 - Alternative servo power

source)

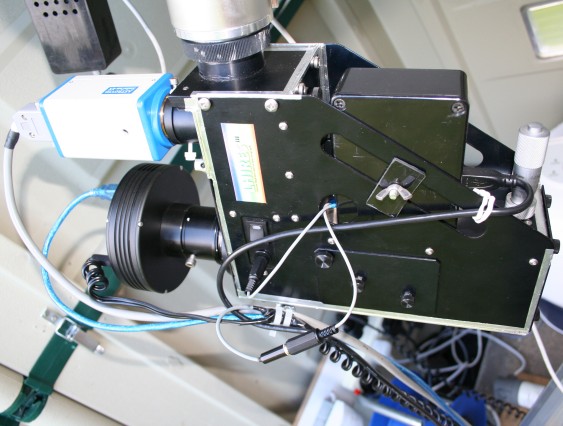

Neon Controller Installed on LHIRES

III

Control is from the PC via the USB cable. (It ended up

running very close to the grating micrometer adjuster!)

The neon

position is controlled by a servo coupled to the rear screw of the neon

shaft.

The 12v power to the neon is separately controlled. This

means the switched off neon can be moved into the beam to act as

a shutter for taking darks.

No permanent modification to the LHIRES

is needed except for replacing the cross head screw on the rear of

the neon axle with a hexagon socket head screw to give a more

positive drive.

The box sits on the top plate of the LHIRES.

It is slid into engagement with the neon axle and clamped to

the side of the LHIRES with the wing

nut.

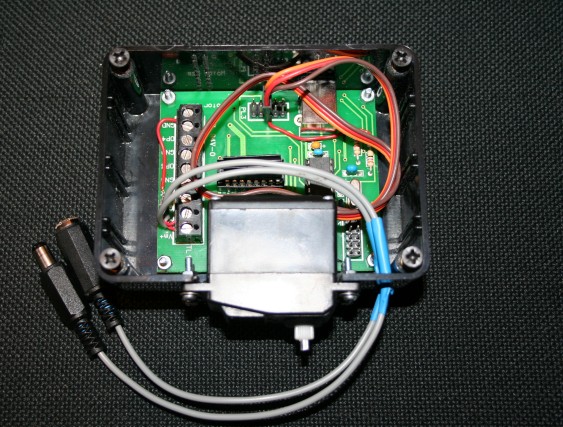

Neon Controller

The servo and circuitry was built into a small

(MB2) project box

The Protech

B305 servo gives plenty of torque to move the neon. The

mounting screws are in slotted holes to allow adjustment to align the

drive shaft to the neon axle.

The drive shaft is short length cut

from a hexagonal allen key. The servo drive shaft was drilled out

until the key was a push fit. It was then glued into

position

Controller Circuitry

A "Motor Bee" control

board is used to control the servo and neon 12v power. It is based on

a PIC IC with a built in USB interface and can control the servo and 4

high power variable outputs, one of which is used to switch the neon

supply. It also has several digital inputs and outputs so has capacity for

future expansion.

The servo was originally powered from the USB 5V

supply. (The red wire from the servo plug to the 5V

side of a resistor on the board.) This needed a powered USB hub to

supply enough current. The controller has now been modified

to include a 5V voltage regulator (7805)

providing the power from the 12v neon supply instead. (Roll your mouse over the image to see the new

layout)

Control Software

The servo calibration is done by positioning the neon shaft half way between the "in" and "out" positions and setting the servo to its neutral position (128) before engaging the servo drive shaft. (The neon shaft is rotated slightly until the hexagonal drive shaft engages). The servo settings are then found which rotates the neon until it is just off the "in" and "out" stops, so that the servo is not under continuous load in either position. (100 and 170 for my setup. Check that the neon position is correct using the guide camera image.)

The neon power is switched on and off with the output 1 set to 255 (maximum)